Anti Reflection coatings

Do you want to reduce the reflection of your plastic or glass? Use the 1-pot Anti-reflection coating (AR) of Kriya Materials. Per side of a coated plastic film or glass sheet, the transmission can be increased up to an average of 2-3 % (400-700 nm) per side of a coated glass or plastic, depending on mechanical requirements, to an average of 3% between 400-700 nm.

When stacked with a hard coat (HC)as base layer, even improved mechanical properties are obtained. The basecoat can be functionalized with additional functionalities such as antistatic, anti-glare or heat absorption.

Advantages of Kriya’s antireflection coating principle are:

√ One-pot system

√ Ready-to-use

√ Cost attractive

√ Compatible with standard wet deposition techniques such as roll-to roll or sheet-to-sheet coaters (e.g. slot die or gravure)

√ No Capex

Anti-reflection performance

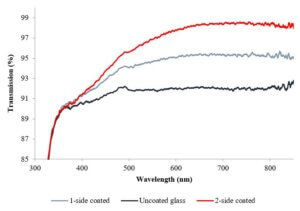

UV-VIS spectra of the Anti-reflection on glass: at a dry film thickness of +/- 120 nm, the transmission gain is up to 3% per side.

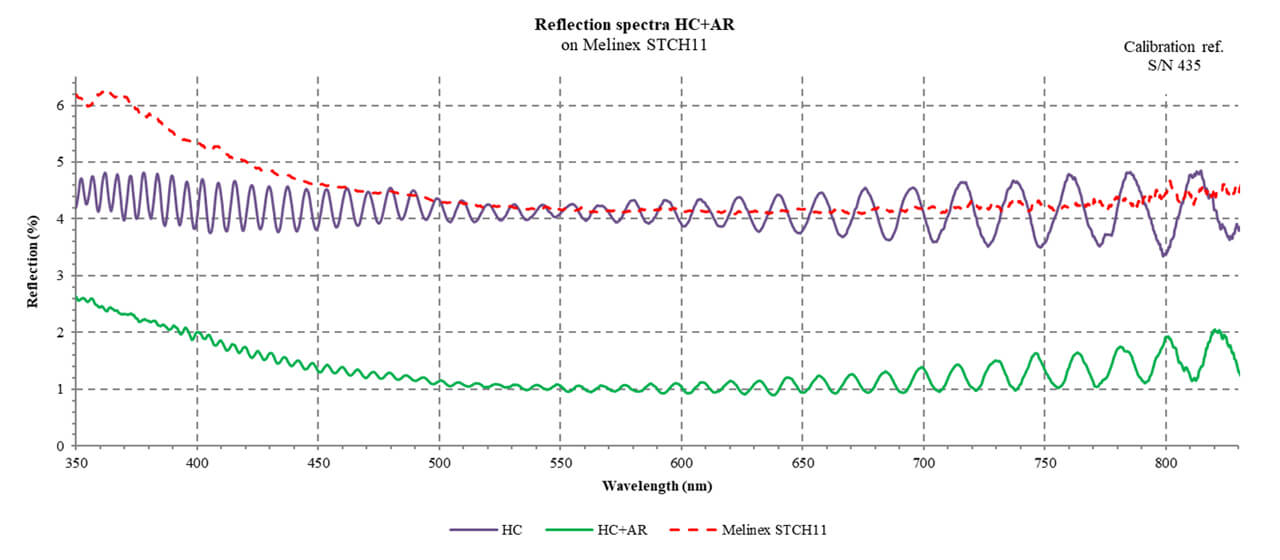

UV-VIS spectra of the Antireflection on PET: The reflection of the plastic can be reduced to an average of 1-1.5 % between 400 and 700 nm. When applying the anti-reflection (AR) on top of a hard coat (HC), mechanical performance against scratches is improved.

Depending on the wavelength (-region) where you need the lowest reflection, dry film thicknesses of this coating ranges from 80-150 nm. Thickness precision of up to 10 nm is required for homogeniety and optimal reflection reduction.

Anti-reflective coating materials

For plastic, the coating solution is:

• Solvent based

• Organic / inorganic

• UV curable coating

For glass, we offer:

• Solvent based

• Mainly Inorganic content

• Thermal curable

Typical applications can be found in displays, windows, and other glazings.

Application method

The anti-reflection coating can be applied using standard wet deposition techniques such as roll coating and slot die, making it the economical choice over conventional AR coatings. The glass coater can determine the position of the minimum reflection through fine tuning the wet layer thickness. Due to the low solid content of this coating, slow and accurate processing is advised for precise and homogeneous thickness control.

Curing technology

On plastics, the coating is standardly cured via H-lamp technology. On request, the coating formulation can be adapted for other curing technologies such as LED curing.

Custom formulations

Kriya Materials always develops custom formulations meeting the most stringent requirements of our customers. The result is a plug and play product designed for optimal performance at the lowest total system cost.

Since we work custom based, we love to hear more about your substrate of interest and envisioned functionalities.

Please contact us through submitting our intake form.